We at Re-PLAST have come up with potential solution to eliminate plastic waste in most effective way; we dispose plastic and make beautiful colourful tiles out of it, at least a better way to eliminate the devil.

Zero landfill is our motto & gifting the coming generations a Zero waste future.

We are the very first company in India to use waste plastic & Concrete all together & we are successfully able to turn into high performance materials that are extensively demanded for their wide spectrum to build pavements, roads, pathways and can be used for outdoor decor and landscaping purposes in both commercial and residential spaces. These tiles are Anti-static, Anti-microbial, Anti-bacterial in nature. Cost effectiveness, durability, sustainable in the long run and in the harsh weathers are the biggest advantage of these tiles.

All Re-PLAST products are made entirely

from recycled waste materials.

Reduced construction cost

Sustainable Technology

Non-Toxic

Recyclable

Low Cost

Lightweight

Damp-proof products

Eco-friendly products

Product Range

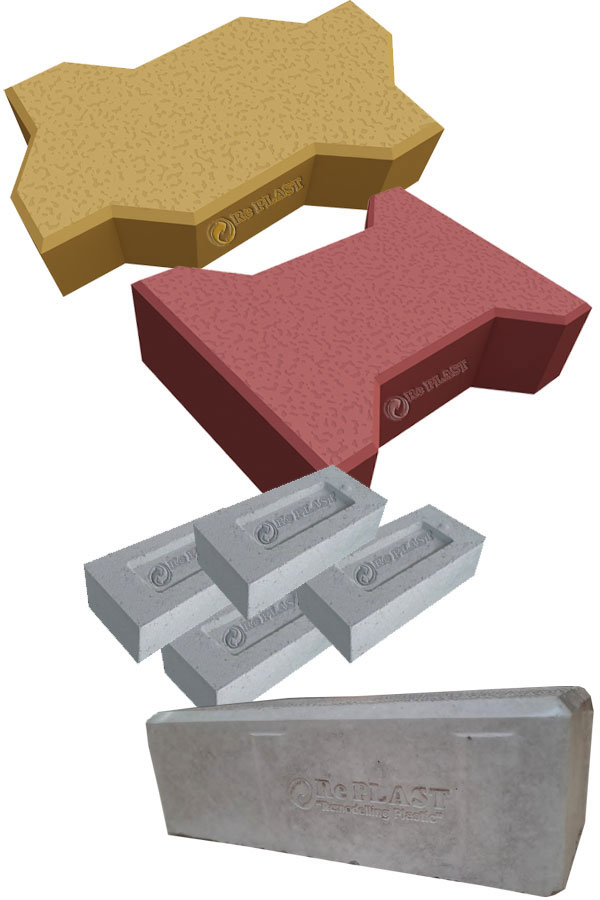

Our plastic pavement blocks are produced with a chemical blend using best blend of multiple materials . These pavement blocks having plastic in them can be widely used for outdoor constructions in the residential and commercial sectors. Our products are unbreakable, durable, anti-static and available at competitive prices.

Re-PLAST Tiles / Pavers

Best suitable for garden, residential, industrial, commercial as well as institute areas having different styles & colors.

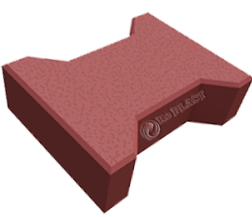

Dumble

Re-PLAST Tiles

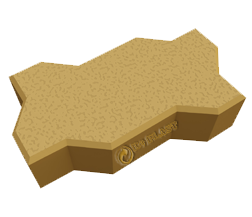

Zebra

Re-PLAST Tiles

Rectangle

Re-PLAST Tiles

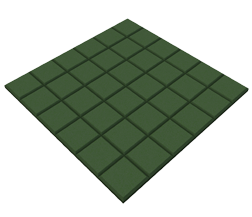

Square

Re-PLAST Tiles

Re-PLAST tiles are available in multiple shapes with beautiful environment friendly colours.

Re-PLAST Flyash Bricks

Best suitable for Industrial boundary walls, Industrial, Commercial and Residential wall buildings having high strength, more durable & low water absorption.

Re-PLAST Kerbstone

Effectively used in pedestrian areas, domestic drives, public, private and commercial footways, school playgrounds, pedestrian precincts and industrial pavements.

Product Gallery

Quality Control

Re-PLAST has been incorporated with a vision of remodeling plastic to blended pavement blocks, this helps our environment to deal and plastic waste and save our environment. This has been made possible through a quality process and idea of remodeling the plastic wastes to pavement block. We are one of the first companies to start the production of plastic blended pavement block in India.

This manual is used to explain the process and quality control measures we take to produce our product i.e, plastic blended pavement block.

Re-PLAST has identified and implemented quality process to provide quality products to our clients. We follow very streamline process right from acquisition of plastic waste, till production of finished material i.e. pavement blocks. Our pavement blocks are very strong and clearly showcase the quality process we are implementing in manufacturing the product and doing research and development for blending.

We regularly inspect the quality process and correct if needed at regular interval.

We promise to:

- Provide safety to our workers

- Takes all measure in safety control

- Maintain government approved process and quality

- Takes care of our team in most suitable way

- Maintain quality of production

- Adhere to our vision and mission while doing production

We have quality manufacturing process define with very clear KRA of respective stake holders.

Every stake holder sin the production cycle is well trained and the entire process is designed to bring out quality production. Each department had team leads and they report to respective managers. There is an important role of quality department, which is headed by quality manager. Blending mixture is the important part during the production of pavement blocks; this mixture is approved by quality control head.

KRA of quality control Head is mentioned below:

- Maintain quality mixture of raw material

- Check the out quality

- Inspect production process

- Train employs for assuring quality in every step of production

- Removes underrated production

- Makes sure each and every tiles is produced with same standard of quality

- Maintain quality balance throughout production

Quality control head procures the plastic from various sources by identifying the type of raw material needed, we make sure that we should not take plastic waste which is of no use for us or which we cannot remodel to blended pavement blocks

We take all necessary measures to make sure we should not increase plastic pollution and takes all necessary steps to control plastic usage in best way in our production unit

We make sure that the plastics are used for the purpose they are bough for that is as blending material in pavement blocks.

By any chance if we receive any category of plastics which is not of our use , we immediately send them back source with all safety concerns in our plant and in logistics

We at Re-Plast carryout the production of plastic blended pavement blocks in most controlled way. We have procured the machineries from certified vendors and take care of pollution and other related government norms.

We have our plant laid out in such a way that it takes care of very compliance in related field. We had organized product plant to produce plastic blended tiles under controlled conditions.

Our finished product is organized and dispatched with the help of a process, which helps us to keep a track of each and every activity.

We take care of proper safety for our workers in plant.

We had taken care of all necessary government approval to run plant.

Re-PLAST blended tiles are thoroughly tested through standard testing procedures by authorized agencies. We only dispatch our finished material post testing the final product.

We follow a process in the dispatch section of our plant. First DC (delivery challan) is raises then only material is dispatch to respective buyer. This helps us to track an record of material in and out and helps us in increasing the efficiency of our plant and it also gives us the information of procuring the raw material in right quality.

We take the customer communicating and feedback very seriously .We urge our customers to gives us complain in writing with proper documentation either in physical or through digital such that we can keep a track of all communication . This also helps in bring the communication to logical closure.

We regularly inspect our quality and process for scope and room of correction, wherever we scope of improvement we immediately act into same.